Pre-Tamping Measurement and Alignment Work Progress | Afcones Infratech

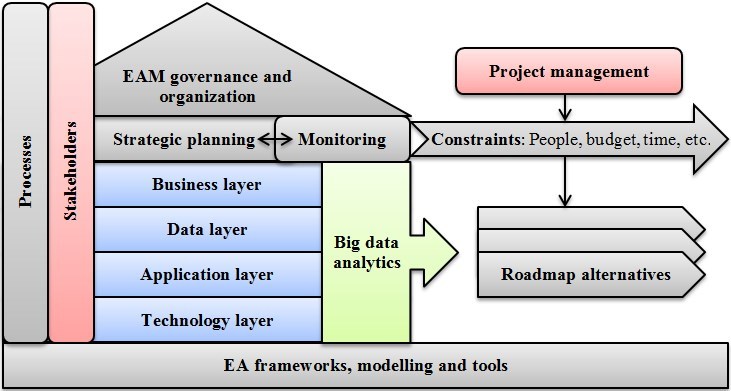

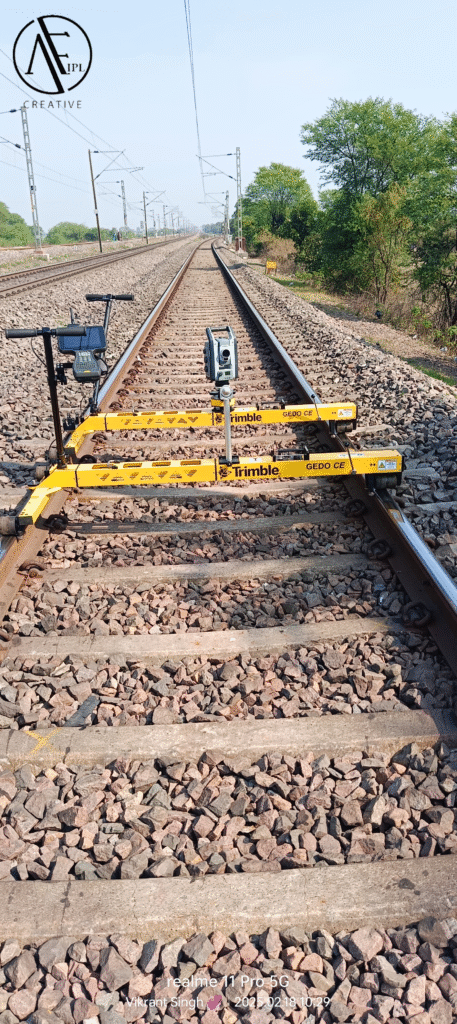

Afcones Infratech Pvt. Ltd. is advancing its commitment to precision and quality through pre-tamping measurement and alignment work on the Puruna–Kanpur railway corridor. By combining GNSS surveying for railways, design alignment preparation, and digital tamping machine input optimization, our team ensures accurate and efficient track construction from the ground up.

1. Importance of Pre-Tamping Measurement in Track 1. Key Activities Completed

1.1 Establishment of GNSS Reference Points

For precise railway track alignment, our survey team has established GNSS reference points at intervals of up to 150 meters. This ensures reliable data for all pre-tamping measurement and alignment work activities. Moreover, these reference points support smooth integration with design alignment and tamping operations.

1.2 Design Alignment Construction

The team processes pre-measurement profiles using advanced design software. Moreover, they construct the Target/Design Alignment by integrating verified GNSS data points. As a result, pre-tamping measurement and alignment work outputs include ALC files, track adjustment files, and Geo Geometry files for precise implementation.

1.3 Generation of Tamping Machine Input Files

To ensure real-time tamping accuracy, engineers generate input files with slew, uplift, and gauge values at every 3-meter interval. Consequently, tamping machine operators can execute alignment and tamping operations efficiently, reducing errors and improving track geometry.

2. Progress and Field Operations

SSo far, 50 km of track have been measured, and trolley operations are progressing smoothly. In addition, our teams are continuously validating survey data to maintain accuracy in all pre-tamping measurement and alignment work.

3. Commitment to Excellence

This milestone highlights Afcones Infratech Pvt. Ltd.’s dedication to delivering railway solutions that combine technology, precision, and field expertise. Moreover, the integration of GNSS surveying for railways and digital alignment methods ensures safe, efficient, and quality track construction.

4. Design Alignment Construction and Data Processing

Following field data collection, the pre-measurement profiles were imported into advanced rail design software for analysis and alignment construction.

The Afcons design team adopted a systematic workflow:

- Filtering and validation of raw geometry data to remove outliers and noise.

- Integration of good data points to reconstruct an accurate existing alignment.

- Comparison between existing and target alignment geometry.

- Generation of the final design alignment using least-squares optimization techniques.

Consequently, the processed data provides a precise Target/Design Alignment. The system exports outputs in ALC format, containing both track adjustment files (with overextension) and Geo Geometry files.

These outputs are directly compatible with tamping machines, allowing real-time control of correction magnitudes. Moreover, each file undergoes multiple layers of verification before being finalized for field implementation.

5. Tamping Machine Input Files and Field Integration

To enable the tamping machine to perform corrections accurately, the design team generates text input files containing slew, uplift, and gauge correction values at every 3-meter interval.

These input files are transferred to the tamping machine control unit, where the onboard system automatically interprets and applies them. Therefore, machine operators can execute tamping operations with minimal manual adjustment and maximum precision.

Additionally, the digital workflow ensures consistency between survey design data and machine operation. The result is a seamless transition from measurement to execution, significantly reducing alignment deviations after tamping.

6. Quality Assurance and Verification Procedures

Maintaining accuracy across multiple field teams and datasets requires a robust quality assurance (QA) mechanism. Afcons has implemented a multi-stage verification process that includes:

- Cross-checking GNSS coordinates with total station observations at critical points.

- Independent verification surveys at random intervals.

- Software-based consistency checks for ALC and Geo Geometry files.

- On-site supervision during tamping to ensure proper file utilization and calibration.

Moreover, all QA procedures follow Indian Railway and RDSO guidelines, ensuring compliance with national standards. The QA documentation serves as a valuable reference for future audits and technical evaluations.

7. Integration of Digital Survey Technology

Afcons has embraced the integration of digital survey and alignment tools to improve speed, accuracy, and traceability. Advanced software solutions streamline data management from field to design and finally to tamping machine interface.

Furthermore, the company utilizes cloud-based data storage to centralize access for design engineers and site managers. This connectivity allows real-time monitoring of survey progress and prompt decision-making when discrepancies arise.

As a result, the entire pre-tamping workflow—from data capture to tamping file generation—becomes transparent, traceable, and highly efficient.

8. Challenges and Mitigation Measures

Executing large-scale pre-tamping work across a 50 km stretch presents multiple operational challenges. These include variable terrain, restricted work windows due to train movements, and environmental constraints.

To mitigate such issues, Afcons implemented several proactive measures:

- Scheduling measurements during low-traffic periods to minimize disruption.

- Using redundant GNSS base setups to avoid signal loss in dense vegetation areas.

- Deploying trained field technicians capable of quick calibration and troubleshooting.

- Continuous coordination between survey, design, and tamping teams through a digital communication platform.

Consequently, the fieldwork proceeded with minimal delay and maintained the desired accuracy threshold throughout the section.

9. Current Status and Progress Achievements

As of this reporting period, 50 km of pre-tamping measurement work has been successfully completed along the Puruna–Kanpur alignment. Trolley operations are progressing smoothly, supported by consistent design and QA workflows.

Moreover, each surveyed segment has been processed and validated, ensuring that tamping input files are ready for immediate use. The achievement underscores Afcons’ capability to handle large-scale, precision-driven railway engineering projects under challenging operational environments.

The company’s project management approach combines engineering discipline, digital integration, and on-ground execution excellence, setting a strong benchmark for future railway modernization works across India.

10. Contribution to National Railway Development

The Puruna–Kanpur pre-tamping initiative is not merely a standalone project; it contributes directly to India’s national goal of modernizing railway infrastructure. Precise alignment and tamping preparation ensure better train stability, reduced maintenance costs, and improved passenger comfort.

Furthermore, digital measurement techniques used here can be replicated across other corridors, promoting a standardized approach to railway geometry management. Afcons’ methodology demonstrates how integrating GNSS, automated design software, and real-time machine input can revolutionize railway construction practices.

11. Commitment to Safety and Sustainability

Beyond technical excellence, Afcons emphasizes safety and environmental sustainability in every project phase. All field activities adhere to strict safety protocols, including personnel training, equipment inspection, and real-time hazard monitoring.

Additionally, the company follows a “minimum disturbance” approach by optimizing work windows and using noise-controlled machinery. As a result, both worker safety and environmental impact remain well within regulatory norms.

These principles ensure that technological advancement does not compromise sustainability or workplace safety—an integral part of Afcons’ operational philosophy.

12. Way Forward

With half of the section completed, Afcons is now accelerating measurement and tamping activities across the remaining corridor length. Future phases will focus on continuous data validation, real-time monitoring, and post-tamping analysis.

Moreover, the team plans to integrate AI-assisted geometry correction analysis, which will further enhance predictive maintenance and long-term track performance. This innovation-driven approach aligns perfectly with Indian Railways’ broader modernization agenda.

Conclusion

Afcones Infratech Pvt. Ltd. Through advanced digital surveying methods, precise data management, and consistent field validation, our team continues to set new standards in railway infrastructure development.

Moreover, the integration of GNSS-based measurements, design alignment construction, and tamping machine input optimization demonstrates our ability to combine technology and engineering expertise effectively.

As we move forward, Afcones Infratech Pvt. Ltd. remains committed to delivering quality-driven, digitally empowered, and technically sound solutions that support India’s growing railway network.

In summary, the project showcases how advanced survey methods, real-time design integration, and disciplined field management can combine to deliver reliable and sustainable railway solutions. Consequently, this milestone reinforces Afcons’ role as a key contributor to India’s modern railway transformation.