Powering the Future with Precision Surveys – Our Ongoing Project with BHEL, Nagpur ⚡

The path to a stronger, more sustainable India begins with reliable power infrastructure — and precision surveys form the foundation of that journey.

At AFCONES INFRATECH PVT. LTD., we take pride in contributing to this national mission through our ongoing project with Bharat Heavy Electricals Limited (BHEL), Nagpur for the 2×660 MW Unit-11 & 12 (BTG–Civil), MAHAGENCO Koradi Project in Maharashtra.

This project marks another milestone in our commitment to engineering excellence, technical precision, and nation-building through innovation.

Geotechnical Investigation at Koradi Power Project – Powering the Future with Precision Surveys ⚡

The path to a stronger, more sustainable India begins with reliable power infrastructure — and Geotechnical Investigation at Koradi Power Project forms the foundation of that journey.

At AFCONES INFRATECH PVT. LTD., we take immense pride in contributing to this national mission through our ongoing collaboration with Bharat Heavy Electricals Limited (BHEL), Nagpur, for the 2×660 MW Unit-11 & 12 (BTG–Civil), MAHAGENCO Koradi Project in Maharashtra.

This project represents another milestone in our commitment to engineering excellence, technical precision, and nation-building through innovation. Moreover, it reflects our dedication to providing data-driven insights that empower the country’s power sector.

🌍 Project Overview

The Koradi Thermal Power Station, operated by MAHAGENCO (Maharashtra State Power Generation Company Limited), plays a vital role in fulfilling the region’s increasing energy demand.

As part of the expansion plan, the installation of two additional units — Unit 11 and Unit 12 (each 660 MW) — will significantly enhance power generation capacity and operational efficiency.

To support this ambitious initiative, BHEL has entrusted AFCONES Infratech to perform the Geotechnical Investigation at Koradi Power Project, along with detailed Topographical and Bathymetric Surveys. Consequently, these investigations deliver critical input data for foundation design, load-bearing analysis, and long-term structural stability — ensuring that every foundation rests on solid ground.

🧭 Scope of Work for Geotechnical Investigation at Koradi Power Project

The scope of our assignment is comprehensive and technically demanding. It includes field surveys, in-situ testing, and laboratory analyses. Furthermore, every operation is conducted with utmost precision and strict adherence to IS standards.

1️⃣ Topographical and Bathymetric Surveys

Accurate mapping forms the cornerstone of any successful design and construction process. Therefore, our survey teams utilize high-resolution total stations, DGPS instruments, and echo-sounders to capture detailed surface and underwater profiles.

This data enables engineers to understand terrain contours, drainage patterns, and sub-surface variations. As a result, we can plan BTG structures with greater accuracy and confidence.

In addition, bathymetric surveys around the cooling water intake and discharge zones help assess bed morphology and sedimentation patterns, which are crucial for hydraulic design and long-term maintenance.

2️⃣ Geotechnical Investigations

Our Geotechnical Investigation at Koradi Power Project covers a wide range of subsoil explorations and field tests. Each activity contributes to identifying soil and rock behavior under various loading conditions.

✅ Boreholes: 150mm diameter boreholes drilled up to 30m depth, combined with Standard Penetration Tests (SPT) for soil strength profiling.

✅ UDS Sampling: Collection of undisturbed samples for laboratory evaluation of compressibility and shear strength.

✅ Core Drilling (Nx size): Execution of rock coring to determine Rock Quality Designation (RQD), recovery, and classification.

✅ Trial Pits: Excavation of 3m x 3m pits to study shallow strata and visually confirm soil conditions.

✅ Plate Load & Cyclic Plate Load Tests: Estimation of bearing capacity and settlement characteristics for shallow foundations.

✅ Cone Penetration, Field Vane Shear, and Resistivity Tests: Continuous assessment of soil resistance and sub-surface uniformity.

✅ Pressuremeter & Crosshole Shear Wave Tests: Evaluation of in-situ deformation modulus and dynamic response.

✅ Block Vibration Tests: Assessment of foundation response to operational vibrations and machine loads.

All these investigations are carefully planned and executed. Consequently, they ensure that data remains accurate, consistent, and representative of actual ground conditions.

3️⃣ Laboratory Testing

After field investigations, all collected samples are subjected to comprehensive laboratory testing at our NABL-accredited facility.

The process includes:

- Grain size distribution, Atterberg limits, and moisture content

- Direct shear, triaxial compression, and unconfined compressive strength tests

- Consolidation, swelling pressure, and permeability assessments

- Chemical analysis of soil, rock, and water for sulphate, chloride, and salinity content

Furthermore, every test strictly adheres to IS, ASTM, and IRC codes, ensuring dependable and reproducible results. Therefore, clients can rely on our data for safe and cost-effective design solutions.

⚙️ Execution Approach

Delivering precision surveys on such a large scale requires meticulous planning and coordinated teamwork. Hence, our execution methodology for the Geotechnical Investigation at Koradi Power Project emphasizes quality, safety, and efficiency at every stage.

Pre-Mobilization Planning

Before mobilization, we prepare a detailed Method Statement and Quality Assurance Plan (QAP). These are reviewed and approved by BHEL’s engineering division. In addition, all equipment undergoes calibration and functional checks to ensure maximum accuracy.

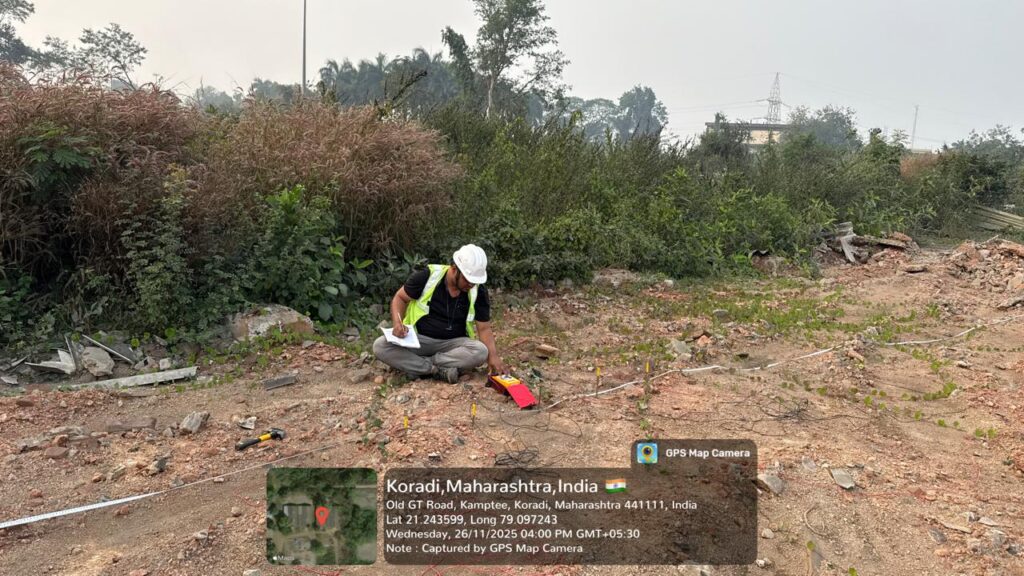

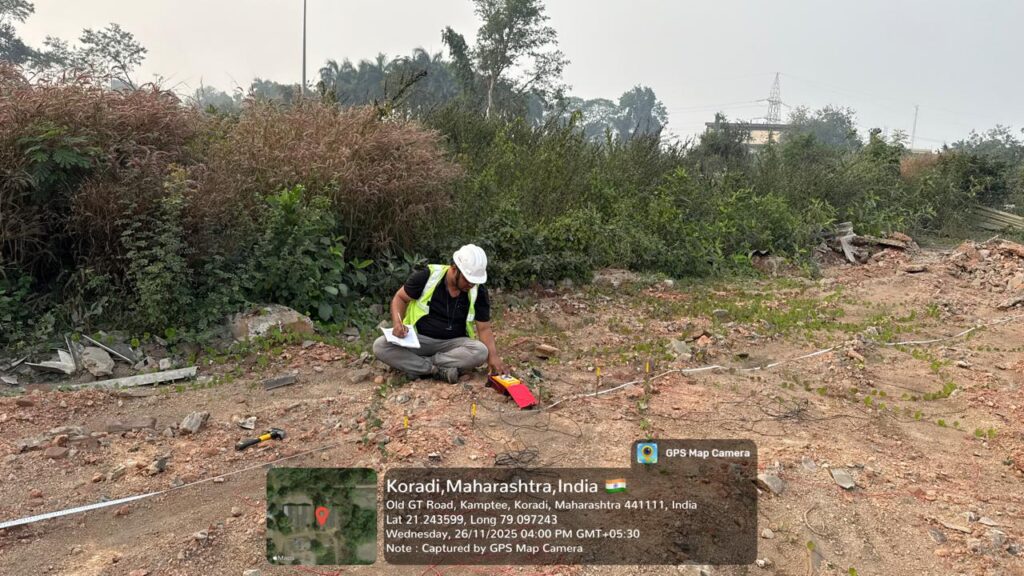

On-Site Supervision

Field operations are continuously supervised by qualified geotechnical engineers. Moreover, progress reports, photos, and instrument logs are maintained digitally for traceability and transparency.

Data Management & Reporting

All field and laboratory data are analyzed using specialized geotechnical software. Consequently, the final report provides borehole logs, soil classification, and engineering recommendations in an easy-to-interpret format.

🧩 Challenges and Solutions

Every major infrastructure project presents unique challenges. The Koradi site, for instance, features varying soil profiles and high groundwater levels. However, our team tackled these obstacles through adaptive planning and innovative field practices.

For example:

- In areas with soft clay, casing pipes and drilling mud were used to prevent borehole collapse.

- In hard strata, diamond-bit core barrels ensured smooth coring and high recovery.

- Additionally, real-time monitoring allowed us to adjust borehole depths efficiently, reducing delays and improving cost-effectiveness.

As a result, we maintained both accuracy and schedule integrity, even under demanding conditions.

🛡️ Safety and Quality Assurance

At AFCONES Infratech, safety and quality form the backbone of our project philosophy. All activities are executed under stringent HSE protocols and in compliance with IS codes such as IS 1892:1979 and IS 2131:1981.

Each day begins with safety briefings, risk assessments, and equipment inspections. Furthermore, our QA/QC team validates every result before submission, ensuring reliability and full compliance with project requirements.

💬 Client Collaboration

Continuous collaboration with BHEL’s project and design teams ensures alignment between on-site observations and design requirements. Therefore, our Geotechnical Investigation at Koradi Power Project directly supports the civil and structural design process.

Regular reviews, discussions, and feedback sessions further enhance project transparency and decision-making speed.

🌱 Sustainability and Environmental Considerations

Beyond technical excellence, sustainability remains central to our approach. We consistently follow eco-conscious drilling practices and minimize disturbance to the surrounding environment. Moreover, we ensure responsible disposal of drilling waste and adhere to all environmental guidelines.

As a result, our work contributes not only to infrastructure growth but also to environmental stewardship.

💡 Building the Foundation for India’s Energy Future

Every borehole, test, and analysis in the Geotechnical Investigation at Koradi Power Project contributes to India’s long-term energy reliability.

Furthermore, by combining advanced technology, skilled professionals, and a passion for excellence, AFCONES Infratech Pvt. Ltd. continues to strengthen the nation’s energy backbone.

Ultimately, our mission is clear — to deliver safe, sustainable, and science-backed engineering for a resilient tomorrow.

🚀 Looking Ahead

Our journey does not end here. In the coming years, we plan to integrate geophysical investigations, GIS-based data visualization, and real-time reporting systems into our projects.

Consequently, these advancements will help clients like BHEL, NTPC, and MAHAGENCO make faster and more informed design decisions.

With continuous innovation, we remain committed to setting new benchmarks in the field of geotechnical and survey engineering.

🔍 In Summary

- Client: Bharat Heavy Electricals Limited (BHEL), Nagpur

- End Client: MAHAGENCO

- Project: 2×660 MW Unit 11 & 12 (BTG–Civil), Koradi, Maharashtra

- Scope: Topographical, Bathymetric, and Geotechnical Investigation at Koradi Power Project

- Deliverables: Borehole logs, test results, and soil classification

- Outcome: Reliable foundation data ensuring stability and longevity of critical infrastructure

⚡ Precision. Passion. Performance.

At AFCONES Infratech, we believe that strong foundations build strong futures. Through our ongoing Geotechnical Investigation at Koradi Power Project, we continue to power India’s energy ambitions — step by step, borehole by borehole — with accuracy, innovation, and commitment.